MG22Eh-5MR

Effective use of organic resources/resource recycling equipment

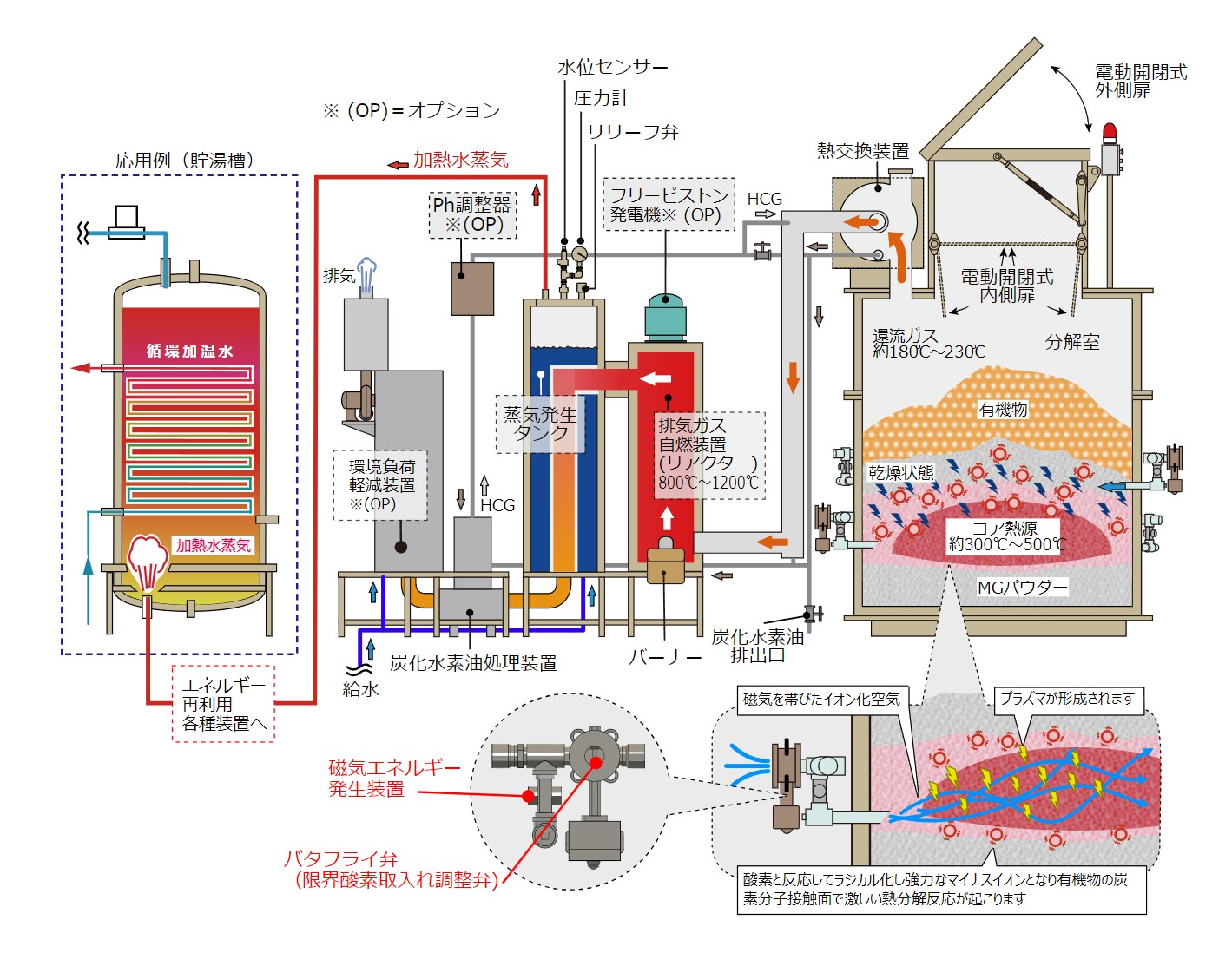

Burning organic matter generates steam which can be used for power generation, hot water and heating.

Organic matter is decomposed and reduced in volume using only magnetism and the heat source inside the device, and steam is created using the heat of decomposition.

Operates 24 hours a day, 365 days a year! Simply feed it in periodically to significantly reduce fossil fuel issues.

Reduces emissions of carbon dioxide and dioxins, meeting environmental standards.

Organic matter that does not contain harmful substances is reduced in volume and the harmless MG powder can be used effectively.

Great durability.

Decomposition occurs at low temperatures with little temperature change, making it highly durable.

Decomposition is automatically controlled according to the temperature inside the device.

In addition, the feed door can be opened and closed by simply pressing a switch.